Raw Cashew Nut Cleaning Machine

Raw Cashew Nut Cleaning Machine Specification

- Power

- 2 HP Horsepower (HP)

- Frequency

- 50 Hz Hertz (HZ)

- Lead Time

- 10 - 15 days

- Product Type

- Raw Cashew Nut Cleaning Machine

- Length

- 310 cm Centimeter (cm)

- Rated Frequency

- 50 Hz Hertz (HZ)

- Material

- Mild Steel

- Dimension (L*W*H)

- 310 x 95 x 120 cm Centimeter (cm)

- Advantage

- Reduces manual labor, improves product quality, enhances processing speed

- Function

- Cleaning raw cashew nuts by removing dust and impurities

- Weight

- Approx. 400 Kg Kilograms (kg)

- Voltage

- 220 - 380 V Volt (v)

- Usage

- Cashew processing industry

- Condition

- New

- Service Period

- 1 Year

- Height

- 120 cm Centimeter (cm)

- Feature

- High cleaning efficiency, robust construction, easy maintenance

- Capacity

- 500 - 700 Kg per hour Kg

- Automation Grade

- Semi-Automatic

- Number of Cleaning Chambers

- 2

- Drive Type

- Electric motor drive

- Noise Level

- Low

- Installation

- On-site support provided

- Application Industry

- Agro-processing, food production

- Maintenance

- Minimal required

- Surface Finish

- Powder Coated

- Spare Parts Availability

- Available

- Mobility

- Fixed with option for caster wheels

Raw Cashew Nut Cleaning Machine Trade Information

- Minimum Order Quantity

- 10 Sets

- FOB Port

- Cat lai port, Hochiminh, Vietnam

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 20 Sets Per Month

- Delivery Time

- 5 Days

- Packaging Details

- 5000 x 2000 x 2500mm

- Main Export Market(s)

- Asia, North America, Africa

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About Raw Cashew Nut Cleaning Machine

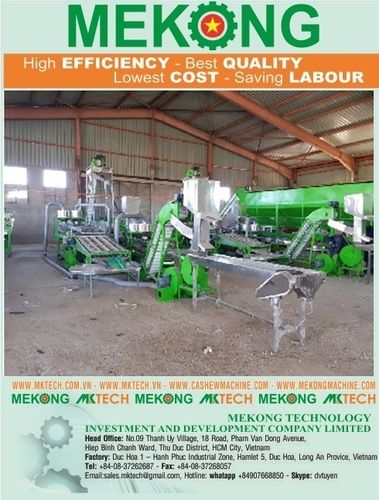

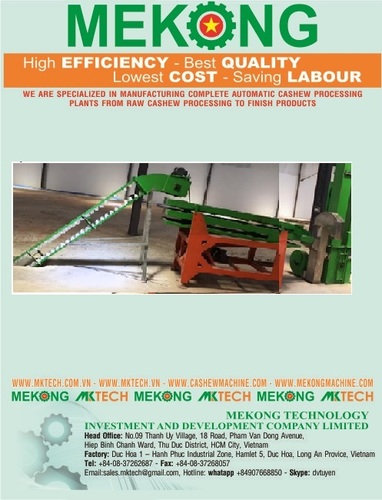

MEKONG Raw Cashew nut cleaning machine is used cleaning dust, plastic, stone mix in Raw cashew nut, to minized destroy blade of cashew shelling machine by stone, The machine is used before raw cashew nut sorting machine, use more in cashew processing factory in the world

The machine can operate independently or in combination with a high-speed, equiped automatic controller help to minimized labour to operation

Specification:

Capacity: 2000 kg/hour

Power Source: 380 V, 3 phase, 50 Hz

Dimemsion: 5000 x 2000 x 2000 mm

Weight: 5000 kg

Robust Construction and High Efficiency

Built from durable powder-coated mild steel, this machine ensures longevity and resistance to industrial wear. The dual-chamber system simultaneously enhances cleaning performance and processing speed, making it suitable for demanding cashew processing operations. With efficient dust and impurity removal, it consistently improves the quality of raw cashew nuts before further processing.

User-Friendly Operation with On-Site Support

Despite its industrial-scale efficiency, the cleaning machine is easy to operate. Semi-automatic controls simplify usage, and on-site installation support ensures seamless integration into your facility. Maintenance is minimal, allowing you to dedicate more time to production rather than upkeep. Spare parts are readily available, adding to the machines reliability and long service life.

FAQs of Raw Cashew Nut Cleaning Machine:

Q: How does the Raw Cashew Nut Cleaning Machine enhance the cashew cleaning process?

A: The machine uses two dedicated chambers to automate the removal of dust and impurities from raw cashew nuts, substantially reducing the need for manual intervention. This ensures consistent cleaning, boosts processing speed, and elevates the final products quality.Q: What is the recommended application industry for this machine?

A: This machine is specifically designed for the agro-processing and food production industries, particularly in settings where raw cashew nuts require thorough cleaning before further processing or packaging.Q: When can I expect delivery and installation support for the machine?

A: The standard lead time for this product is 10 to 15 days. On-site installation support is provided to ensure correct and efficient setup at your facility, regardless of location within Vietnam or for exporters.Q: Where is the machine typically installed within a processing plant?

A: Due to its fixed design, the machine is commonly installed in the primary cleaning section of cashew processing facilities. For added flexibility, optional caster wheels are available, allowing for repositioning if necessary.Q: What maintenance is required for optimal machine performance?

A: Minimal maintenance is needed thanks to its robust construction and powder-coated finish. Routine checks for cleanliness and mechanical integrity ensure consistent performance, and spare parts are available for quick replacements if needed.Q: How does the machine benefit cashew processors operationally?

A: By automating the cleaning stage, the machine significantly reduces manual labor, enhances processing speed, and ensures a higher-quality finished product. These benefits make operations more cost-effective and scalable for both small and large processors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cashew Nut Processing Machine Category

Automatic cashew shelling line MEKONG-10H2

Price Range 20000.00 - 26000.00 USD ($) / Set

Minimum Order Quantity : 10 Sets

Condition : New

Dimension (L*W*H) : 15 x 5 x 2.5m Meter (m)

Product Type : shelling and separating raw cashew nut

Raw Cashew Nut Sizing Machine

Price Range 5000.00 - 10000.00 USD ($) / Set

Minimum Order Quantity : 1 Set

Condition : New

Dimension (L*W*H) : 14 x 2 x 2.5 Meter (m)

Product Type : Sorting size of raw cashew nuts

Cashew Kernel Grading Machine

Price 5000 INR / Unit

Minimum Order Quantity : 100 Units

Condition : New

Product Type : Grading Machine

Cashew Nut Humidification Room

Price 12000 USD ($) / Unit

Minimum Order Quantity : 10 Units

Condition : New

Dimension (L*W*H) : 5000 x 2000 x2000 Millimeter (mm)

|

MEKONG TECH CO. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry